IMS Bearing: The Facts Made Simple

References: LN Engineering, Autohaus Hamilton, Porsche

If you’re a late model Porsche owner, you would have heard the acronym IMS but every time you’ve jumped on the internet, you’ve come away with more questions than answers.

We’ve spent the time in the workshop speaking with our technicians and distilling the very best factual information about IMS bearings, their importance and what exactly does go wrong. Below you’ll find the most commonly asked questions regarding the IMS bearing along with a simple easy to understand explanation of the issues!

We hope this will help you have a better overall grasp of what exactly the IMS bearing is, what goes wrong and what is involved to make sure it doesn’t happen to you.

What is an IMS bearing?

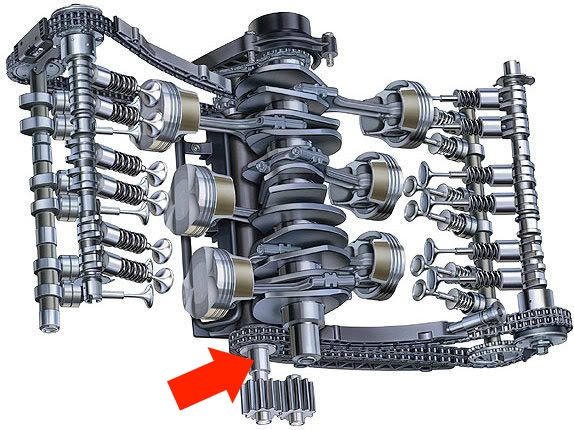

IMS stands for ‘Intermediate Shaft’, and the IMS bearing supports the intermediate shaft, on the flywheel end of the motor. The purpose of the intermediate shaft is to drive the camshafts indirectly off the crankshaft. By using an intermediate shaft, the speeds of the chains are reduced, which is better for the chain life. This basic design was used through the entire lifespan of air-cooled six-cylinder Mezger engines used through to 1998. The inclusion of an intermediate shaft which drives the camshafts indirectly off the crankshaft has been a mainstay of the horizontally-opposed flat 6 engine utilised by Porsche.

The same design has been retained with the water-cooled Turbo, GT2 and GT3 models as their engines are based off the same 964 engine case with the same internals as the earlier air-cooled engines. Although these engines use an intermediate shaft, with a bearing, they have a fundamentally different design, and are not subject to the same type of failure as the M96 engine.

What Porsche models are prone to IMS failure and would benefit from an IMS upgrade.

- All 986 Boxster models.

- 987 Cayman & Boxster models up to engine number 61504715

- All 996 models (not including: GT and Turbo models)

- 997 3.6ltr with M96/05 up to engine number 6950745

What actually goes wrong?

There are so many reasons for bearing failure, and usually each failure is due to a combination of causes, not just a single cause. Spalling (Define: Spalling) occurs as a result of normal fatigue where the bearing has reached the end of its normal lifespan but this is not the most common cause of IMS failure. Spalling detected in bearings can generally be attributed to other factors; a common cause of bearing failure is due to high load and lack of lubrication to the IMS bearing, causing continuous over heating. This will ultimately weaken the bearing and fracture it, leaving behind a jagged depression (or a ‘pit’). Once this cycle begins, wear is greatly accelerated and the bearing will fail prematurely.

What is the worst case scenario?

In worst-case scenarios, the cam timing can also be thrown off, causing valve to piston contact. In that case, the engine will need a full strip down and rebuild.

One thing is for sure; once you have experienced an IMS bearing failure, there is NO turning back. A complete engine disassembly is required to replace the intermediate shaft and in most cases, complete rebuild or engine replacement is your ONLY option.

Are there any warning signs?

There are three warnings signs which can indicate a bearing is failing; you’ve found metallic debris in the oil filter while carrying out an oil change, or you may have found that there’s an oil leak located at rear of engine, or you would have started to hear knocking and metallic sounds coming from the rear of the motor.

It’s important as soon as you spot or hear the problem, call us on (02) 9417 0911 for some advice. Do not drive the car until it has been inspected by a trained Porsche technician, as you could cause catastrophic engine damage and failure.

What can be done to fix this common problem? - LN Engineering IMSsolution

LN Engineering are considered both pioneers and leaders in this area and have currently sold over 30,000 retro fit kits worldwide extending the life of Porsche engines.

The Ball and Roller, IMS bearing upgrades are still required to be replaced as part of regular preventative maintenance however there is another long lasting replacement also available from LN Engineering.

The same minds that developed the IMS Retrofit kit developed the “IMSsolution”. This team is considered North America’s foremost M96 experts.

The “IMSsolution” from LN is a patented solution that is designed for the life of the engine, it does not have a service or replacement interval. The IMSsolution eliminates the ball bearing and replaces it with an oil pressure fed plain bearing.

At Autohaus Hamilton we are constantly evolving our recommendations as our suppliers offer us new products to keep our customers on the road and enjoying their Porsche passion. The IMSsolution from LN Engineering is a longer term solution for engines with IMS issues and that is why we are now only supplying and fitting the LN IMSsolution over other retrofit solutions.

If you believe your IMS bearing is due for a replacement and would like to update to the LN Engineering “IMSsolution” please let our service team know.

Need more help?

We hope we’ve been able to shine some light and help you have a better understanding of what exactly an IMS bearing is and what can actually go wrong with them.

To discuss the best approach for your car, give our service team a call on (02) 9417 0911 or email service@autohaushamilton.com.au

Photos of IMS bearing failures:

CATASTROPHIC ENGINE FAILURE, CAUSE: IMS BEARING FAILURE

IMS BEARING FAILURES:

For any information or to book a service contact the workshop here.